Defining an IBC Tote

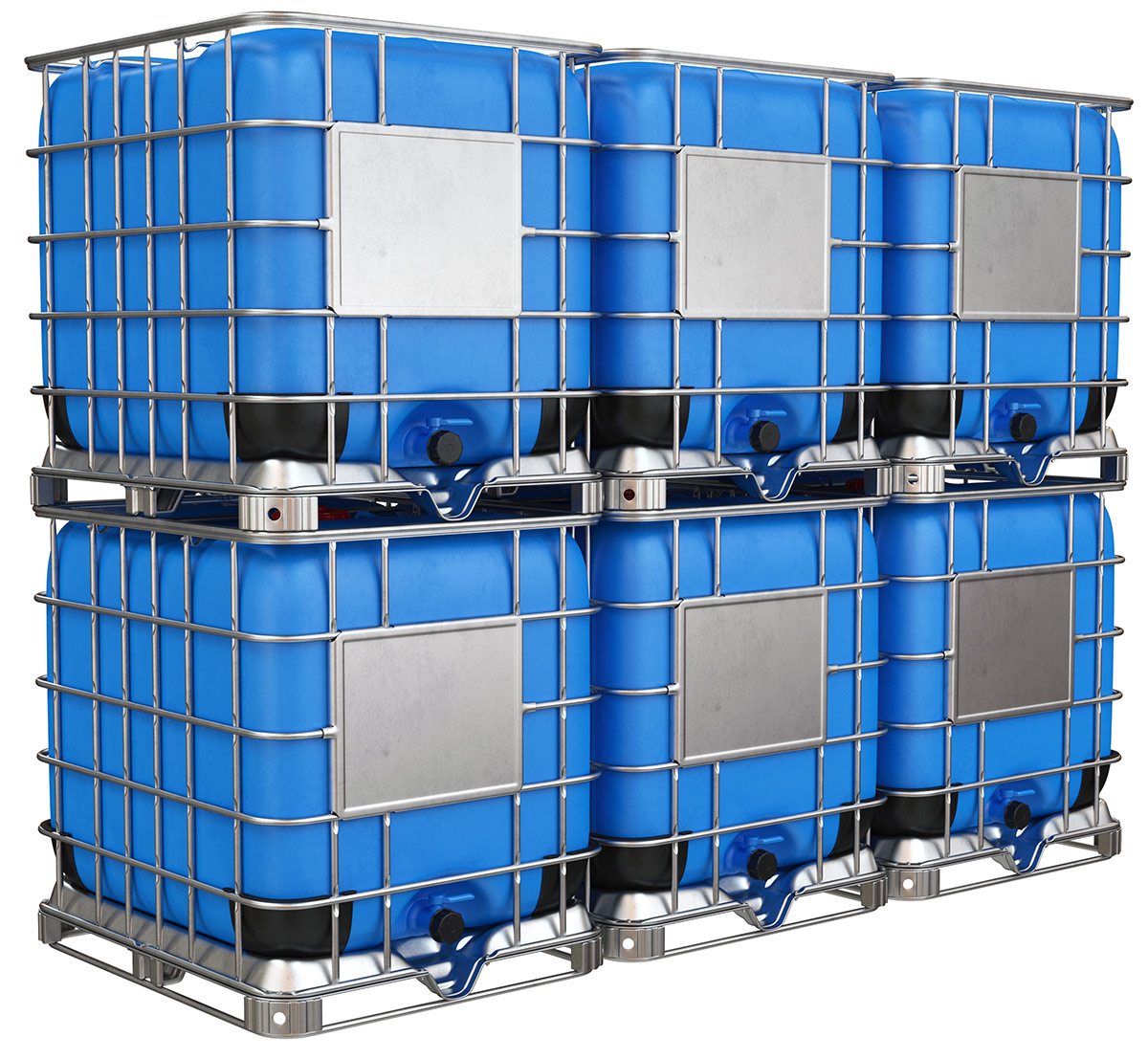

IBC totes are vessels designed to safely store and transport bulky liquids and dry ingredients. They are either square or rectangular-shaped containers with nozzles and valves to allow you to pour liquids into the tank and empty it easily. The valves are typically at the front and have an opening that allows you to attach a hose to transfer the liquid into another container. IBC tanks also have clamps that apply pressure on the valves to prevent the liquid from seeping out.

Another vital part of the IBC tote tank is the gauge that lets users measure the volume of the content inside. IBC totes come with a steel cage to protect the container from damage and keep it balanced during transport and storage. They also have pallets at the bottom made from wood, plastics, or metal.

A gasket seals the spaces between the lid and the tank to prevent leakage when in transit. Their cube shape makes them easily stackable, allowing you to make the most of your warehouse’s storage space.

What Are IBC Totes Used For?

Most companies use intermediate bulk containers to safely store and transport hazardous chemicals like ethanol, methanol and benzene. Stainless steel IBC totes prevent the tank from exploding when transporting chemicals. The tanks have a fusible vent that allows vapor to escape once the internal temperature reaches a specific range to prevent an explosion.

Some people also use these containers to store and transport water, especially in construction sites or events that require a constant water supply and have no access to a water main. The agricultural industry uses tote tanks to ship fertilizers and pesticides. They even store and transport edible food items like grains. The pharmaceutical and cosmetic industry uses IBC tanks to transport pills, powders and liquids. They can also store fuel, sand, and hazardous waste.

Types of IBC Totes

IBC totes fall into two main categories, rigid and flexible. Rigid IBCs are made from galvanized tubular steel, iron, hard plastics or a combination of plastics and metals. On the other hand, the flexible IBC tanks have a plastic inner liner and a flexible outer shell made from heavy-duty materials like woven polypropylene or polyethylene. The sides fold inwards, allowing for efficient packing and shipping when empty. We can categorize IBC totes in the following ways based on their application or materials.

Stainless Steel IBC

Stainless steel tote tanks are made from a durable corrosion-resistant material, making them ideal for heavy-duty tasks across different industries. You can use them to store and transport bulk chemicals, flammable liquids and high-temperature items. Stainless steel totes can ship items via air, sea, trains and motor vehicles. They have a lifespan of about 20 years.

Carbon Steel IBC

Carbon steel IBC is one of the most durable options with shock-resistant properties. You can use it to store or transport items with strong odors like perfumes, cleaning chemicals, oil, lubricants, paints and dyes. They are more lightweight and affordable than stainless steel tote tanks.

Plastic IBC

Plastic IBCs are the most commonly used options due to their versatility. They are made from high-density polyethylene. Plastic tote tanks do not rust and can withstand impacts.

IBC Tank Heaters

These IBC totes have an electric heater that heats the content to maintain their proper viscosity when in transit. It’s ideal for products like honey, biofuel and molasses. These tanks come with an insulating fabric that you can wrap around to prevent heat from escaping. You won’t have to keep reheating it and you can monitor the tank temperature to keep it in the correct range.

Benefits of Using IBC Tote Tanks

The packaging solution you choose will determine how long your products will remain in perfect condition. Investing in the proper storage containers will help you save money and time. Here are some benefits of using IBC tote tanks.

Easy to Transport

When transporting liquids with drums, you must place them on a pallet or shrink-wrap them tightly to prevent spillage. But you can move the IBC tanks freely without putting them on a pallet. You can also safely stack them on top of one another for efficient storage. The steady galvanized iron tubular cage in most of these IBCs adds more stability during transit. You can easily attach the containers to a forklift to help you unload your entire inventory as quickly as possible.

Reusable

You can use the IBC totes for a long time before replacing them, which will help you save money in the long run. This makes tote tanks an environmentally friendly alternative. If you have an IBC tank that you no longer use, you can resell it to another user. They will only need to hire professional cleaners to intensely clean the tank to remove chemicals, debris and other possible contaminants before use.

Versatile

IBC tote tanks are made from various materials that allow for multiple applications across industries. Their capacity ranges from 110 to 550 gallons, accommodating most commercial and industrial storage and transportation needs. They can handle industrial chemicals, hazardous materials and food products. With their tightly locking tops, they can perform extra functions like beer fermentation in the brewing industry.

Durable

IBCs are made from solid, sturdy materials that withstand harsh weather conditions. The robust construction ensures protection from nails, rust, splinters or foreign objects that can damage the tank, causing leaks. The cages protect them from shock and other interference while in transit. IBC totes can handle impacts and strains during truck and rail shipping.

Cost-Effective

Shipping containers are a significant expenditure for businesses that handle bulk shipping. So, any solution that can help cut storage costs will make a big difference in the long run. Usually, most companies use 55-gallon steel drums to transport bulky fluids. But the round drum shape leaves a lot of unused space. IBC maximizes space utilization which can help cut storage costs.

Tote tanks have a larger capacity for shipping large quantities of goods at once. IBCs can benefit companies that want to ship large amounts of liquids that need portioning later. This way, you can transport the content in one container rather than several smaller ones. IBC tote tanks will help you save on labor costs since your workers can move large batches of liquids in a single trip. With fewer moving containers, your employees can focus on more demanding tasks.

Affordable

You can buy shipping boxes and IBC totes at a reasonable price online or even get a used one at a significantly lower cost. This makes them accessible to small and startup businesses. Their versatility allows you to use them in place of other expensive industrial equipment like mixing tanks and fermenters. You can even rent out an IBC tote tank if you only need it for short-term use. If you seasonally need the IBC tote tanks, renting them will help eliminate non-working assets in your business.

Cut Down on Product Waste

When using drums, it’s hard to drain out all the liquid inside. You will likely end up with residues that build up and stay on the sides, resulting in waste. But the easy-to-clean design of an IBC tote tank enables you to retrieve every bit of the product. Its airtight nature also helps prevent spillage cutting down on waste. Since the containers reduce spills, they minimize injury and accidents rate.

Things to Consider When Buying an IBC Tote Tank

When buying an IBC container, you must determine your exact storage need and research your industry requirements. Here are tips to guide you in choosing the most appropriate option.

Pick a Suitable Material

Review the tote tank types mentioned above and pick an option that best suits the nature of your business. Chemical IBC tanks must meet FDA, DOT/UN and ASME standards. On the other hand, pharmaceutical totes should have silicon rings that make the tank airtight. You can use them for powder, pills and drug capsules. These tanks should have full traceability to allow users to track the load when in shipment.

Food grade IBC must be highly hygienic. They must adhere to the set food safety regulations. Check for DOT/UN markings on the side walls to identify food grade IBC totes. These marks indicate that the tank is made from safe materials to prevent contamination. They should also be easy to clean. If you buy a used tote, the seller should provide details on how they used the container. Never use totes that previously handled pharmaceuticals, hazardous waste or chemicals for food storage. This can lead to contamination.

Consider the Size

Determine the tote’s volume size and choose an option that can adequately hold your products. Most of them have a standard base of around 45 by 45 inches. The height may vary based on the volume of construction. The most common sizes are 275 and 300 gallons. Larger tanks will always cost more. Consider smaller totes if you need to move your products around the warehouse frequently. But when choosing an IBC tote container, always pick a bigger size to accommodate future business growth.

Read Through Requirements

Review the IBC container’s materials to ensure they meet the product’s legal storage requirements. If you intend to store flammable liquids, ask the seller if your preferred tote can handle such a function. In this case, you will need a container that meets National Fire Protection Association recommendations to minimize fire risks and other hazards. Use only approved materials like stainless steel for combustible elements. Plastic totes can increase fire risks.

Inquire also about the inspection requirements. Note that IBC totes need a leak-proof test before their first use. If you intend to use it for transporting goods, you must have it tested externally every two and a half years. Metallic, composite and rigid plastic IBCs require internal inspections after every five years. So if you buy a used IBC, ask the seller for the last leak-proof test and inspection dates. If you are the initial owner of the totes, do not skip inspections since they greatly affect the container’s durability.

Consider the Price

Used totes cost lower than new ones, but it’s good to compare the price difference and gauge whether it’s reasonable. Pay more attention when buying a used tote for food storage. You will need to research the material used and clean it thoroughly before use.

To avoid such hassles, you can buy a new tote. Alternatively, you can opt for reconditioned IBCs, inspected, treated and certified by professionals. They have qualities similar to brand-new totes but come at a lower price.